Delivering Vapor-Proof Seals and Cutting Costs with Emabond Plastic Welding Technology

The Plastic Welding Challenge

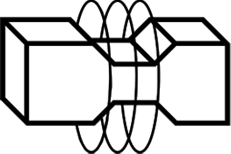

A leading manufacturer of radon fan housings needed a more reliable and cost-effective method of product assembly. Their previous approach relied on bolts and custom gaskets to hold housings together. Not only did this add significant cost per unit, but it also introduced points of potential leakage in an application where “vapor-proof” performance is highly sought after. Complicating matters further, the housings had to protect expensive internal components, making reliability and serviceability just as important as cost reduction.