Bridging the Un-Weldable

For decades, engineers have faced the same frustrating limitation: you can’t reliably weld dissimilar polymers like polycarbonate (PC) and thermoplastic polyolefin (TPO) or polypropylene (PP).

Different melt temperatures, incompatible chemistries, and low surface energy made these materials notoriously difficult, forcing manufacturers to rely on adhesives or fasteners.

Those compromises are not necessary.

Emabond’s custom-engineered molecular welding technology allows true structural fusion between these polymer families, without adhesives, solvents, or surface pretreatments.

The Breakthrough: Custom Resin Chemistry Meets RF Energy

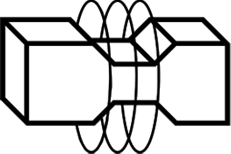

Emabond’s proprietary RF-activated bond layer is chemically tuned to be compatible with both sides of the joint.

When exposed to a focused electromagnetic field, it generates localized heat, internally creating a molecular interlock between the mating polymers.

The result:

- Permanent structural Welds between PC–TPO and PC–PP assemblies.

- No surface marking, no flash, no residue.

- Fully hermetic seals suitable for outdoor, electronic, and consumer environments.

- Fast weld times, scalable for automated production.

This capability transforms how designers think about multi-material construction, especially for housings that must balance mechanical strength, transmission, and aesthetic precision.