Delivering Leak-Proof, Lightweight Coolers with Advanced Plastic Welding

The Plastic Welding Challenge

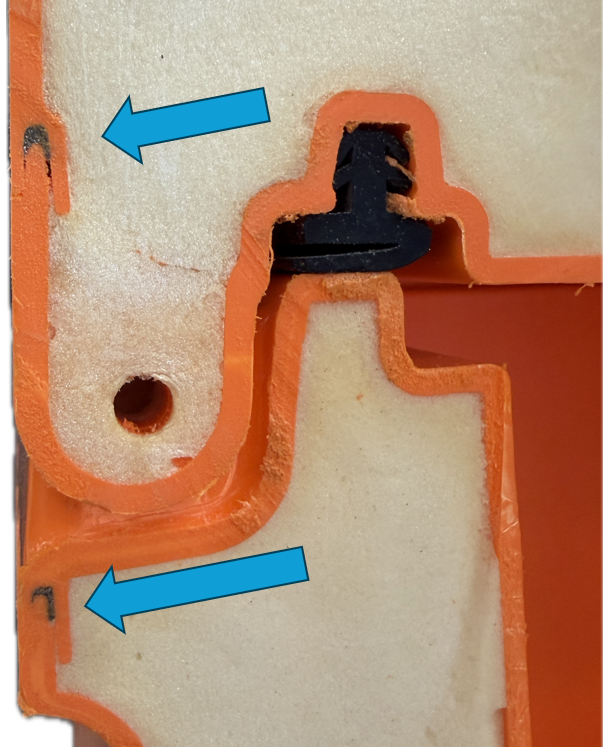

A leading insulated cooler manufacturer wanted to move beyond rotational molding and glue, which limited design possibilities, increased costs, and added unnecessary weight. The market demanded highly aesthetic products durable enough to withstand rugged outdoor adventures and highly efficient at keeping contents cold. However, traditional roto-molding and hot plate joining processes created thick walls, distortion, and limited insulation options, making it difficult to meet both performance and visual quality expectations.