Tangible Results with Cost-Saving Benefits:

- Airtight Reliability: Welds maintained zero pressure decay over 100,000 test cycles, ensuring long-term durability and unmatched product performance.

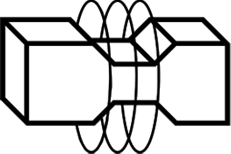

- Dissimilar Material Bonding: Produced high-strength welds between talc-filled PP and TPV with bonds stronger and longer-lasting than adhesives.

- Geometry Flexibility: Delivered consistent welds across three separate large-diameter seams, totaling more than 80”.

- Production Efficiency: Eliminated adhesives and cure time, cutting costs and accelerating manufacturing throughput.

Emabond’s Lasting Impact

Emabond material is specially formulated to join dissimilar materials in a fraction of the time that adhesives take, leaving cleaner, more reliable welds capable of remaining airtight under daily use. These durable, airtight welds helped transform the innovative seating stool into a product that exceeds performance expectations and stands up to demanding lifecycle testing. The solution not only ensured durability but also created a more cost-efficient and scalable manufacturing process, laying the groundwork for long-term product success.