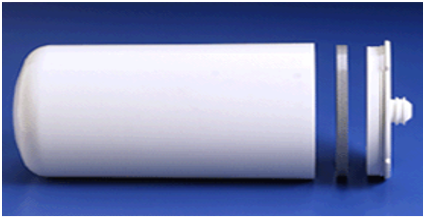

Achieving Higher Burst Pressures and Reliability with Emabond Welding Technology for Food Service Water Filters

The Plastic Welding Challenge

Emabond is the go-to solution for major food service water filter OEMs needing a plastic welding solution capable of withstanding extreme performance demands to protect the integrity of drinking water and their brand’s reputation. Traditional spin welding presented significant challenges. Excess flash created risks of contamination, and the process often struggled to consistently achieve the required burst pressure and hermetic sealing performance. Production teams battled with high scrap rates, slowing efficiency and raising costs.

The Food Service Water Filters Required:

- High burst pressure exceeding 500 psi.

- Numerous model variations across sizes and designs

- Weld line diameters from 2” to 4”

- Clean, flash-free joints with no particulate contamination.

- NSF 61 Compliance for potable water applications.

- Read about Product Certification here:

Emabond’s Plastic Welding Solution

Emabond provided the superior alternative by leveraging our patented custom-blended welding material and electromagnetic welding technology. We optimized joint design with step geometry for optimal shear height and strength, ensuring scalable performance across weld line diameters. Using custom profiles and injected molded gaskets specially formulated for joining heavily talc-filled polypropylene, Emabond technology achieved fully hermetic and flash-free seals capable of reaching higher burst pressures.