Lasting Hermetic Seals in Dissimilar Materials, Even in Harsh Environments

The Plastic Welding Challenge

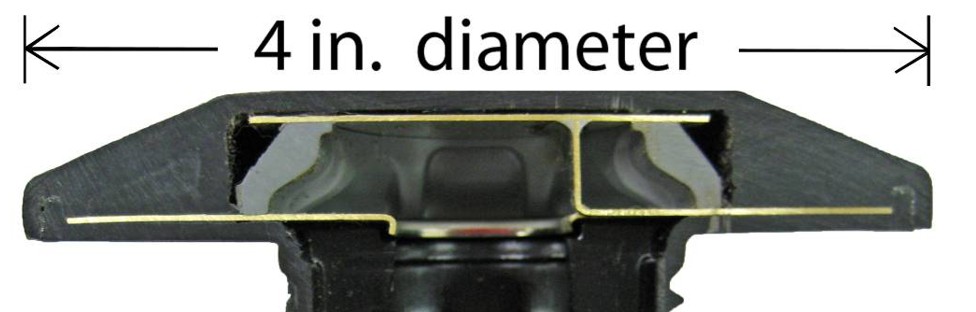

Outdoor water meter endpoints are critical utility devices that house delicate metal transmitters that must function reliably for decades. These housings need to prevent moisture, chemicals, and trauma from damaging the internal components while being exposed to temperature swings and fluctuating weather conditions. To complicate matters, the design required joining dissimilar materials, PC/ABS to TPO, something that conventional welding technologies consistently failed to achieve. Spin, vibration, or laser welding either introduced flash, couldn’t maintain a hermetic seal, or simply wasn’t capable of dissimilar material bonding.